This Is How You Can Find the Correct Box Size

Disclaimer: The following instructions are intended for licensed electricians who have the necessary skills and experience to perform electrical work safely and correctly. This guide is only meant to refresh your memory and does not cover all the details or variations that may apply to your specific situation. This guide is not a substitute for proper training and certification, but rather a refresher of the basic steps and precautions involved in installing or repairing electrical systems. You must always follow the national and local electrical codes and regulations that govern your area. Failure to do so may result in serious injury, property damage, or legal consequences.

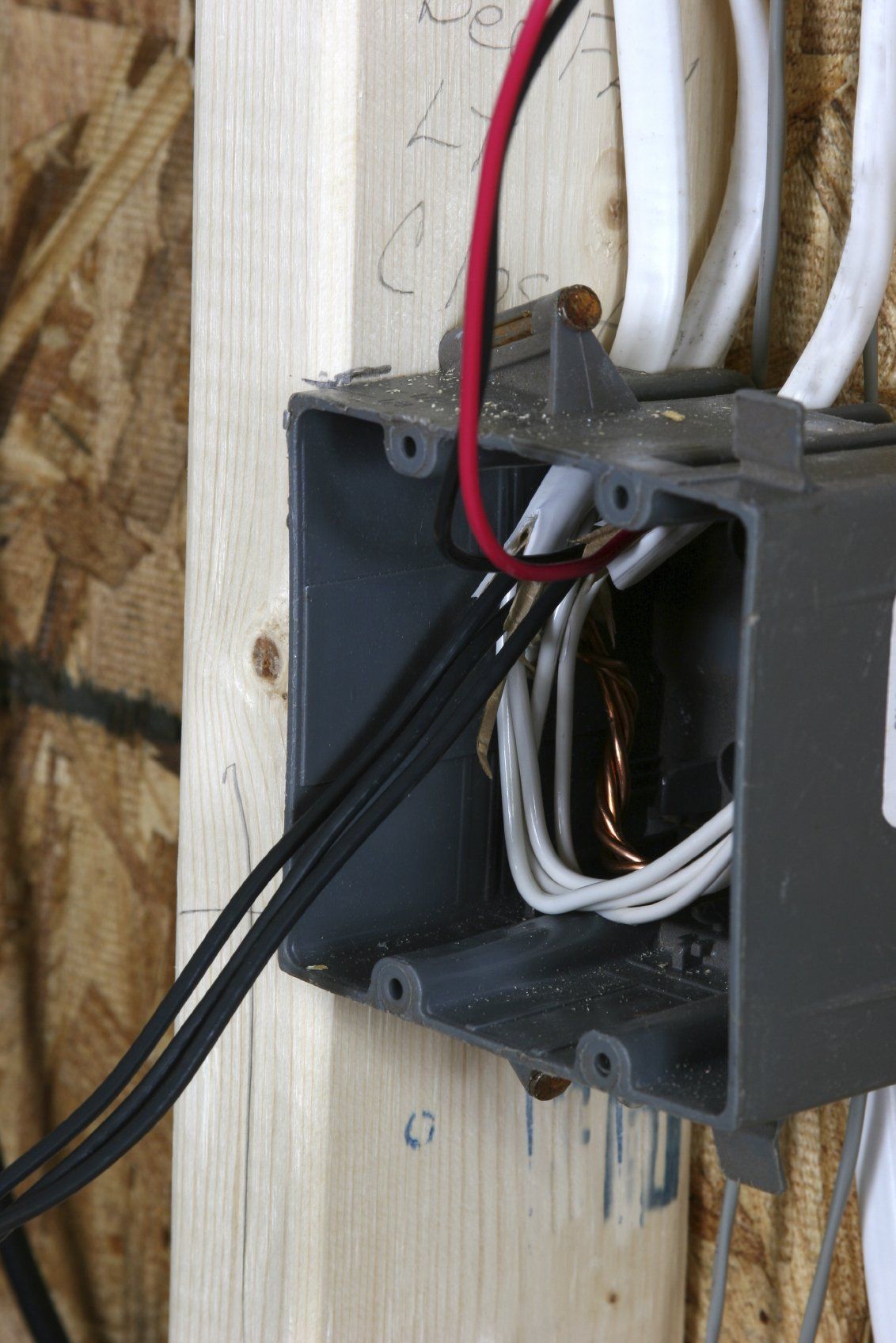

If you are planning to do some electrical wiring in someone's home or office, you may wonder what kind of electrical box you need to use. Electrical boxes are metal or plastic enclosures that house wires, switches, outlets, and other devices. They protect the wires from damage and provide a secure connection point for the devices.

But not all electrical boxes are created equal. Depending on the number and size of wires you are working with, you need to choose an electrical box that has enough space to accommodate them safely and comply with the National Electrical Code (NEC). Here we will explain how to determine the correct size of electrical box for your wiring project using some simple guidelines and calculations.

Why Box Sizing Matters

Box sizing is important for several reasons:

- It prevents overheating of wires and devices. If an electrical box is too small for the number of wires it contains, it can cause excessive heat buildup inside the box. This can damage the insulation of the wires and create a fire hazard.

- It prevents short circuits and arcing. If an electrical box is too small for the number of wires it contains, it can cause them to bend sharply or touch each other. This can create a short circuit or an arc fault, which can result in sparks, shocks, or fires.

- It ensures proper grounding and bonding. If an electrical box is too small for the number of wires it contains, it can interfere with the grounding and bonding connections of the wires and devices. This can compromise their safety and performance.

- It complies with code requirements. The NEC sets minimum standards for box sizing based on various factors such as wire size, wire type, device type, conduit type, etc. Failing to meet these standards can result in code violations, fines, or penalties.

How to Choose the Right Box for Your Wiring Project

One of the most important aspects of any wiring project is choosing the right box for your wires. The box is where you connect and protect your wires from damage and fire hazards. If you use a box that is too small or too large for your wires, you may run into problems such as overheating, short circuits, loose connections, or code violations. The National Electrical Code (NEC) provides guidelines for box sizing based on the number and size of wires you're working with. The NEC specifies the minimum volume of the box in cubic inches (cu. in.) that you need to accommodate your wires. To find out the required volume of your box, you need to follow these steps:

- Identify the type and size of your wires. Different types of wires have different capacities and thicknesses. For example, a 14-gauge copper wire can carry up to 15 amps of current and has a diameter of about 0.064 inches, while a 12-gauge copper wire can carry up to 20 amps and has a diameter of about 0.081 inches.

- Count the number of wires that will enter the box. You need to count each wire that passes through or terminates in the box as one wire. You also need to count any devices that will be installed in the box, such as switches or receptacles, as two wires each.

- Add any allowances for clamps or fittings that will be used in the box. Some boxes have built-in clamps or fittings that secure the wires to the box. These clamps or fittings take up some space in the box and need to be accounted for in your calculation. The NEC provides specific allowances for different types of clamps or fittings depending on their size and shape.

- Multiply the number of wires by their volume factor according to their size and type. The NEC provides a table that shows how much volume each wire occupies in cubic inches based on its gauge and material (copper or aluminum). For example, a 14-gauge copper wire has a volume factor of 2 cu.in., while a 12-gauge copper wire has a volume factor of 2.25 cu.in.

- Add up all the volumes from steps 2, 3, and 4 to get the total required volume for your box.

- Compare your total required volume with the actual volume of your box. You can find out the actual volume of your box by checking its label or measuring its dimensions (length x width x depth). Your actual volume must be equal to or greater than your required volume; otherwise, you need to use a larger box.

Here is an example:

Suppose you want to install a single-pole switch in a plastic octagonal ceiling box with four 14-gauge copper wires entering it: two hot wires (black), one neutral wire (white), and one ground wire (green). How do you determine if this box is big enough for your wiring project?

First, you count how many wires will enter the box: four individual wires plus one device (the switch) equals five wires.

Second, you add any allowances for clamps or fittings: since this plastic octagonal ceiling box has no built-in clamps or fittings, there are no allowances needed.

Third, you multiply each wire by its volume factor: four 14-gauge copper wires have a total volume factor of 8 cu.in., while one device has a total volume factor of 4 cu.in.

Fourth, you add up all the volumes: 8 + 4 = 12 cu.in.

Fifth, you compare this total with the actual volume of your box: according to its label, this plastic octagonal ceiling box has an actual volume of 15 cu.in., which is more than enough for your wiring project.

Therefore, this plastic octagonal ceiling box is suitable for installing a single-pole switch with four

14-gauge copper wires.

Choosing the right size box for your wiring project is essential for safety and efficiency reasons.

By following these simple steps based on NEC guidelines, you can ensure that your wiring project meets code requirements and avoids potential hazards.

How to Size Electrical Boxes by Volume

The volume of an electrical box is measured in cubic inches (cu.in.). It represents how much space is available inside the box for wires and devices. To determine if an electrical box has enough volume for your wiring project, you need to calculate how much volume each wire and device takes up inside the box. The NEC provides a table (Table 314.16(A)) that lists how much volume each wire size requires based on its type (solid or stranded) and insulation (THHN/THWN-2/T90). For example:

- A 14 AWG solid THHN/THWN-2/T90 wire requires 2 cu.in. per wire

- A 12 AWG stranded THHN/THWN-2/T90 wire requires 2.25 cu.in. per wire

- A 10 AWG solid THHN/THWN-2/T90 wire requires 2.5 cu.in. per wire

- A 8 AWG stranded THHN/THWN-2/T90 wire requires 3 cu.in. per wire

You also need to add extra volume for other components inside the box such as:

- Grounding wires: add one volume allowance based on the largest grounding wire size entering the box

- Cable clamps: add one volume allowance based on each cable clamp used inside or outside of metal boxes

- Devices: add two volume allowances based on each device (switch or outlet) installed in metal boxes; add one volume allowance based on each device installed in nonmetallic boxes

- Hickeys: add one volume allowance based on each hickey used inside metal boxes

Once you have calculated how much volume each component takes up inside your electrical box,

you need to compare it with the actual volume of your chosen electrical box.

The NEC provides another table (Table 314.16(B)) that lists how much volume various types and sizes of standard metal boxes have.

For example:

| Type | Size | Volume |

| Square | 4 x 1¼ inches | 21 cu.in |

| Square | 4 x 1½ inches | 25 cu.in |

| Square | 4 x 2⅛ inches | 30½ cu.in |

| Octagon | 4 x1¼ inches |18 cu.in |

| Octagon |4 x1½ inches |21½ cu.in |

You can also find nonstandard metal boxes and nonmetallic boxes with different volumes.