This Is How You Can Prevent Electrical Shocks

Disclaimer: The following instructions are intended for licensed electricians who have the necessary skills and experience to perform electrical work safely and correctly. This guide is only meant to refresh your memory and does not cover all the details or variations that may apply to your specific situation. This guide is not a substitute for proper training and certification, but rather a refresher of the basic steps and precautions involved in installing or repairing electrical systems. You must always follow the national and local electrical codes and regulations that govern your area. Failure to do so may result in serious injury, property damage, or legal consequences.

Insufficient Electrical Bonding: Why You Should Follow the NEC Guidelines

Electrical bonding is a process of connecting metal parts of an electrical system to establish electrical continuity and conductivity. Bonding ensures that all metal parts are at the same potential and provides a low-impedance path for fault currents to flow back to the source. Bonding also reduces the risk of electric shock and fire by preventing voltage differences between metal parts that could cause arcing or sparking. The National Electrical Code (NEC) is a set of standards that regulate the safe installation of electrical wiring and equipment in buildings and structures. The NEC contains specific requirements for grounding and bonding of electrical systems, which are intended to protect people and property from hazards arising from the use of electricity.

Grounding is a process of connecting an electrical system or equipment to earth, or to a conductive body that extends the earth connection. Grounding provides a reference point for the voltage of an electrical system and helps stabilize it against fluctuations. Grounding also facilitates the operation of overcurrent devices, such as circuit breakers and fuses, by providing a path for fault currents to flow. The NEC requires different types of grounding and bonding for different types of electrical systems and equipment. For grounded systems, which have one conductor intentionally connected to earth, such as most residential and commercial systems, the NEC requires:

- Electrical system grounding: This involves connecting the grounded conductor (usually neutral) of an electrical system to a grounding electrode system (GES), which consists of one or more conductive objects buried in or near the earth, such as ground rods, metal water pipes, concrete-encased electrodes, etc. The GES provides a direct connection between the electrical system and earth.

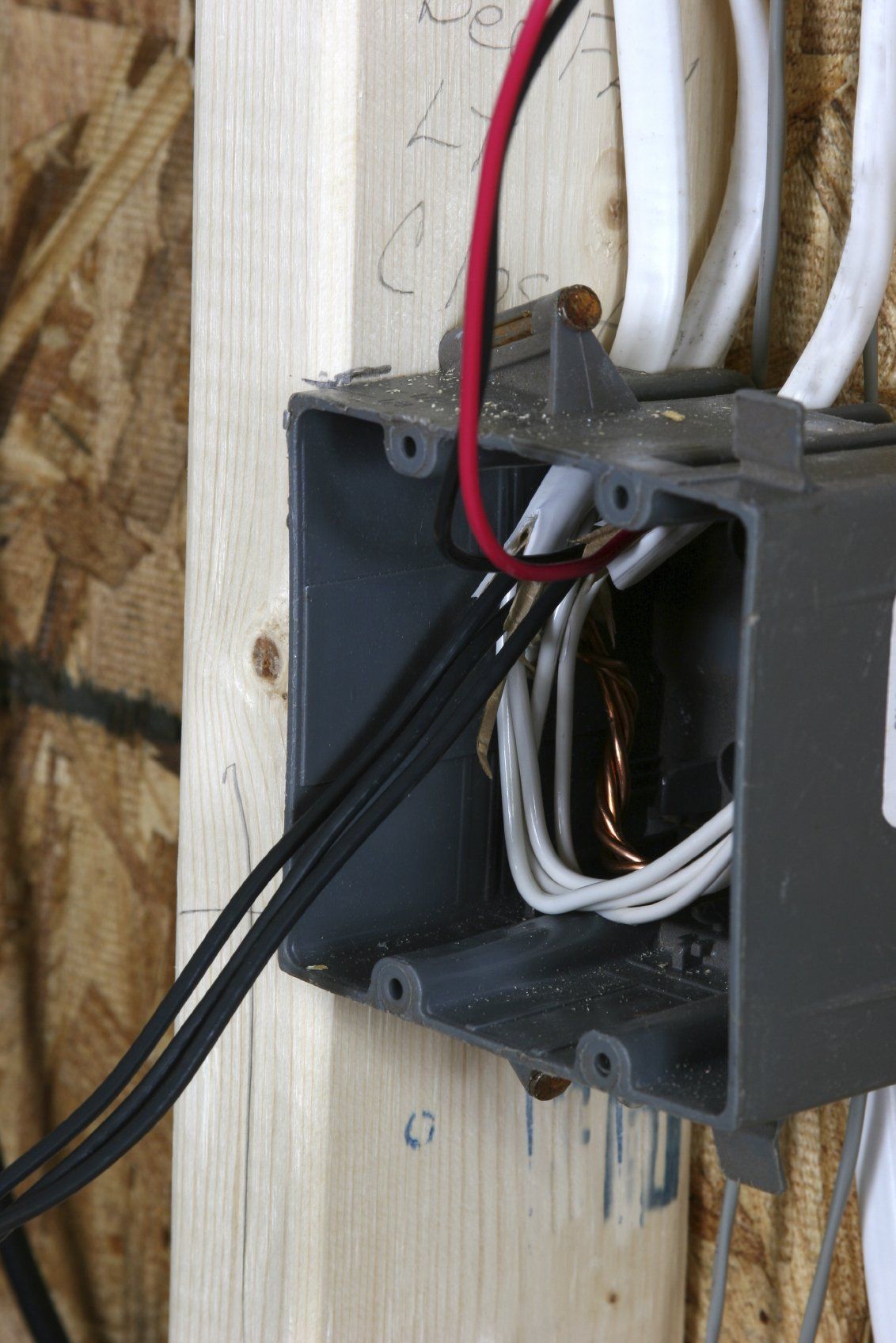

- Electrical equipment grounding: This involves connecting non-current-carrying metal parts of electrical equipment, such as enclosures, raceways, conduits, cabinets, etc., to an effective ground-fault current path (EGFCP), which is a low-impedance path that can safely carry fault currents back to the source. The EGFCP usually consists of equipment grounding conductors (EGCs), which are wires run along with circuit conductors that connect equipment grounds to system grounds.

- Electrical equipment bonding: This involves connecting exposed non-current-carrying metal parts that are likely to become energized due to contact with live parts or induced voltages, such as metal frames, pipes, ducts,

- ladders, etc., to an EGFCP. This prevents these metal parts from becoming hazardous by limiting their voltage difference with respect to other grounded parts.

- Bonding of electrically conductive materials: This involves connecting electrically conductive materials that are not part of an electrical circuit but may be located near one, such as gas piping systems, structural steel members, metal fences, etc., to an EGFCP. This prevents these materials from becoming sources of ignition or shock by eliminating potential differences between them and other grounded parts.

For ungrounded systems, which have no intentional connection to earth, such as some industrial and health care systems, the NEC requires the same types of grounding and bonding except for electrical system grounding.

Insufficient electrical bonding can result in serious consequences,

such as:

- Electric shock: If a person touches two metal parts that have different potentials due to insufficient bonding, they may receive a harmful electric shock. This can cause injury or death depending on the severity of the shock.

- Fire: If insufficient bonding causes arcing or sparking between metal parts, it may ignite flammable materials nearby, such as gas vapors, wooden structures, or insulation materials. This can cause fire damage or explosion hazards.

- Equipment damage: If insufficient bonding causes excessive fault currents to flow through equipment components that are not designed to handle them, it may damage or destroy them. This can cause malfunctioning or failure of critical devices, such as motors, transformers or control panels.

To avoid these risks, it is essential to follow the NEC guidelines for electrical bonding when installing or maintaining electrical systems and equipment. The NEC provides detailed rules on how to select appropriate bonding methods and materials based on various factors, such as:

- Type and size of electrical system and equipment;

- Location and environment;

- Available grounding electrodes;

- Fault current levels;

- Load characteristics;

- Special conditions; etc.

The NEC also specifies minimum requirements for testing and verifying the effectiveness of bonding connections, such as:

- Resistance measurements;

- Continuity tests;

- Visual inspections; etc.

By following the NEC guidelines for electrical bonding, you can ensure that your electrical installations will prevent most shocks and fires.